FIMMWAVEA powerful waveguide mode solver |

|

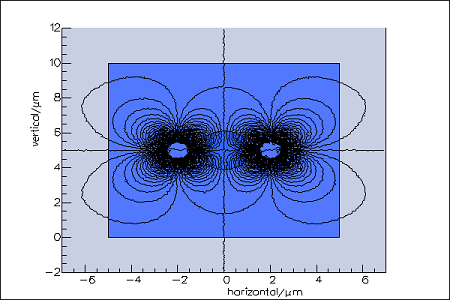

Stress SolverSimulating stress fields in waveguides with FIMMWAVEThe Stress Solver for FIMMWAVE allows the FIMMWAVE user to calculate the stress fields in a waveguide and the consequential perturbation of the waveguide modes. The Solver supports thermally-induced stress fields – typically generated during cooling of a device constructed from materials with different thermal expansion coefficients. The model is a two dimensional model based on the plane strain assumption The device is considered to be long along its z axis in comparison to it’s cross section and the strain in the device along the z axis is considered to be zero. The Solver is based on the finite element method.

The Solver operation is straight forward – the user enters thermal expansion coefficients, Poisson’s ratio, Young’s modulus data and the photo-elastic constants for each material in the device, via the usual FIMMWAVE Material Database. The user then enters two temperatures – the first temperature at which the device is assumed to be at zero stress, and the second usually lower one, the temperature at which the stress calculation is desired. Features

Applications

|